THE ART & SCIENCE OF STEEL WELDING

Mechanical works are the backbone of any welding and fabrication company, contributing significantly to the successful execution of projects. From conceptualisation to design, fabrication, and installation, mechanical expertise plays a crucial role in ensuring the quality, durability, and safety of the final products. This writeup explores the vital role of mechanical works in a welding and fabrication company, highlighting its importance in achieving precision and fostering innovation.

Role of Mechanical Works in Welding and Fabrication:

Design and Planning:

Mechanical engineers collaborate with design teams to translate conceptual ideas into practical and functional designs. Their expertise helps in optimising structural integrity, material selection, and overall aesthetics of the fabricated components.

Material Selection:

Choosing the right materials for various projects is paramount. Mechanical engineers analyse properties like strength, corrosion resistance, and thermal conductivity to ensure the longevity and performance of the final product.

Fabrication Techniques:

Mechanical engineers are responsible for selecting appropriate fabrication methods such as cutting, bending, welding, and machining. They ensure that the chosen techniques are efficient, cost-effective, and suitable for the specific project requirements.

Quality Control:

Rigorous quality control is essential to guarantee the safety and reliability of fabricated components. Mechanical engineers develop testing procedures and inspection protocols to identify defects and deviations from design specifications.

Welding Processes:

Welding is a core aspect of fabrication. Mechanical engineers choose the appropriate welding methods (MIG, TIG, SMAW, etc.) based on the materials involved, joint types, and project specifications. They ensure that welds meet industry standards for strength and durability.

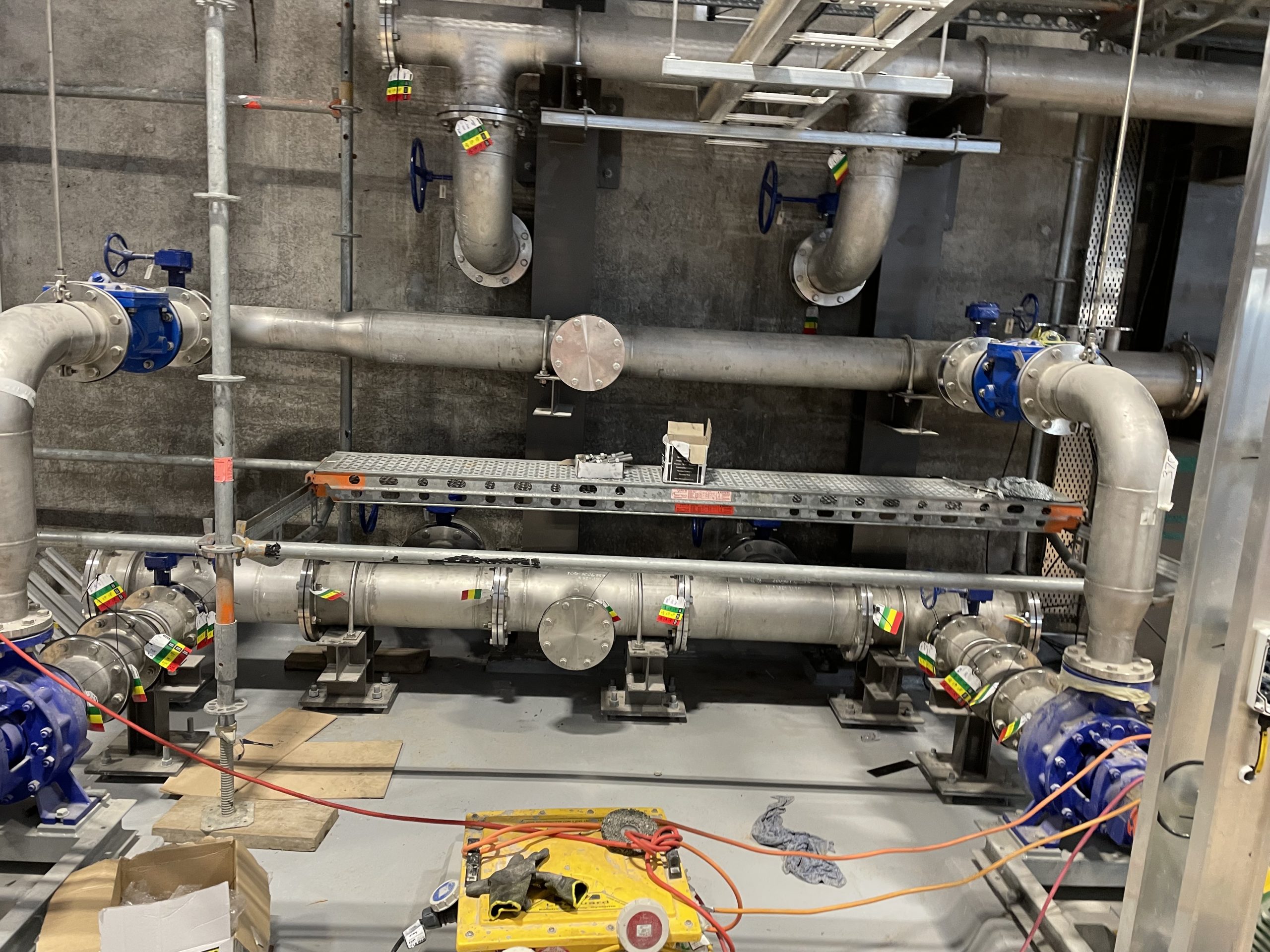

Assembly and Installation:

Mechanical engineers supervise the assembly and installation of fabricated components. They ensure proper alignment, fit, and functionality of parts, minimising the risk of errors during the final stages of production.

Importance of Precision

Precision is paramount in welding and fabrication, as even minor deviations can lead to catastrophic failures in structures and equipment. Mechanical engineers contribute to precision by utilizing advanced computer-aided design (CAD) software, simulations, and prototyping. This meticulous approach minimises errors, reduces rework, and enhances the overall quality of the final product.

Mechanical engineers drive innovation by exploring new materials, fabrication techniques, and automation solutions. They keep up with industry trends, advancements in metallurgy, and emerging technologies such as additive manufacturing (3D printing). By integrating these innovations, welding and fabrication companies can create unique and cutting-edge products that meet modern demands.

Mechanical works are the cornerstone of a welding and fabrication company, ensuring that projects are executed with precision, quality, and innovation. The expertise of mechanical engineers spans from design and material selection to fabrication techniques and quality control. Their role in achieving precision and fostering innovation is crucial for producing safe, durable, and groundbreaking products in the welding and fabrication industry.

Power Of

Precision

Fostering

Innovation

-

What is the role of mechanical engineers in a welding and fabrication company?Mechanical engineers play a pivotal role in designing, planning, selecting materials, choosing fabrication techniques, ensuring quality control, supervising assembly, and fostering innovation within the company.

-

What factors influence material selection for welding and fabrication projects?Factors such as the project's structural requirements, environment (corrosion resistance), load-bearing capacity, thermal properties, and budget constraints are considered by mechanical engineers when selecting materials.

-

What are some common welding methods used in fabrication?Mechanical engineers may choose from various welding methods such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), SMAW (Shielded Metal Arc Welding), and more, based on the specific requirements of the project.

-

What role does computer-aided design (CAD) play in welding and fabrication?CAD software allows mechanical engineers to create detailed and accurate designs, simulate the behaviour of components, identify potential issues, and make necessary adjustments before the fabrication process begins.

-

How does precision contribute to the success of welding and fabrication projects?Precision ensures that fabricated components meet design specifications and function as intended, minimising the risk of defects, failures, and the need for rework.

-

What are some examples of projects that require precise mechanical works in welding and fabrication?Examples include building structural frameworks, manufacturing industrial machinery, constructing pipelines, creating specialised equipment, and fabricating custom-designed architectural elements.